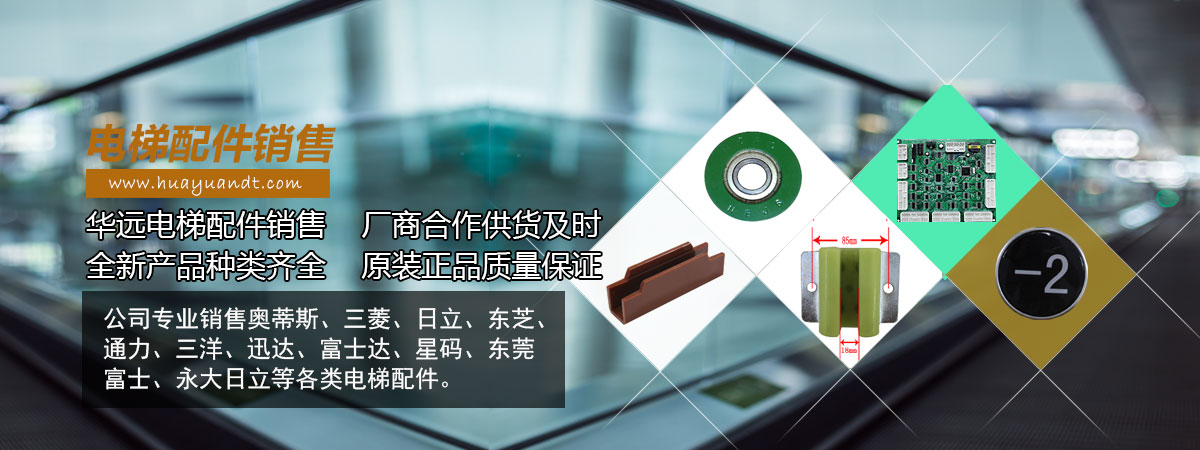

天水華遠電梯維保有限公司成立于2015年11月,注冊資本120萬元,2016年12月取得甘肅省質量技術監督局特種設備安裝改造維修許可證。許可經營電梯的維修保養業務;一般經營電梯及電梯零配件銷售;智能化辦公設備、監控設備、車閘設備的銷售及安裝售后服務;照明電器材料、水暖材料、裝修材料的銷售業務。

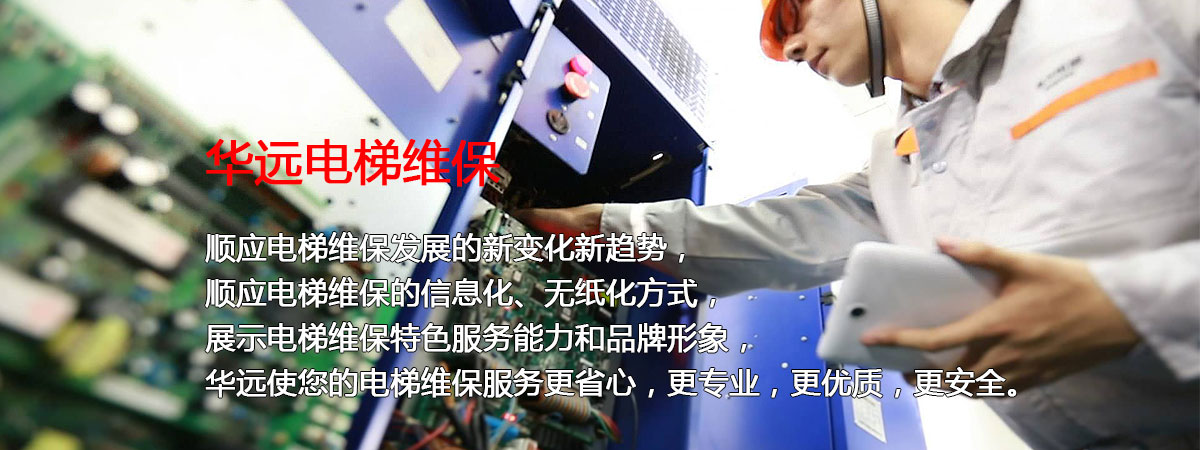

華遠電梯維保公司創建以來,融入創新的管理理念……

版權所有:天水華遠電梯維保有限公司

電話:0938-8317846 傳真:0938-8317846 地址:天水市秦州區新華路77號 郵編:741000

技術支持:陜西心海網絡

隴ICP備17004941號-1